Raw Material Reduction for Furnaces

Executive Summary

To tackle mounting raw material waste and energy inefficiencies, a sophisticated AI-based optimization system was deployed in an advanced steel manufacturing facility.

Key outcomes included:

-

10% reduction in raw material usage

-

12% decrease in energy consumption

-

15% improvement in furnace efficiency

-

Full return on investment within 12 months

This transformation not only yielded direct cost benefits but also supported long-term sustainability and compliance goals.

Challenge

Tackling Operational Inefficiencies

The steel plant operated large-scale furnaces used for melting and heat treatment processes. However, several operational limitations were affecting performance and profitability:

Inconsistent Furnace Temperatures

Resulting in non-optimal combustion and thermal inefficiency.

Improper Fuel-Air Ratios

Causing excessive fuel use and raw material waste.

Manual Adjustments

Dependent on operator intuition rather than predictive analysis.

Rising Operational Costs

Due to inefficient energy use and material wastage.

Regulatory Pressures

Increasing need to comply with energy efficiency norms and emission standards.

These issues culminated in higher production costs, greater environmental impact, and limited responsiveness to real-time operational deviations.

Solution

AI-Based Optimization for Furnace Operations

To resolve these challenges, a comprehensive AI-based optimization system was introduced. The solution encompassed a multi-layered technological approach:

1. Hardware Deployment

-

IoT Sensors: Installed to monitor temperature, pressure, fuel flow, and material input in real time.

-

Actuators: Enabled automated adjustments to the fuel-air mixture and furnace temperatures.

2. Software Integration

-

Predictive Analytics: Machine learning models forecasted optimal furnace settings based on historical and live data.

-

Anomaly Detection: Automatically identified performance deviations or inefficiencies.

-

Optimization Engine: Continuously optimized combustion and temperature parameters for maximum output.

-

Dashboard Interface: Provided real-time visualization of efficiency metrics, material usage, and energy consumption.

3. System Integration

-

Seamlessly integrated with the plant’s existing SCADA and MES systems for centralized control and monitoring.

Outcome

Transformative operational and financial results

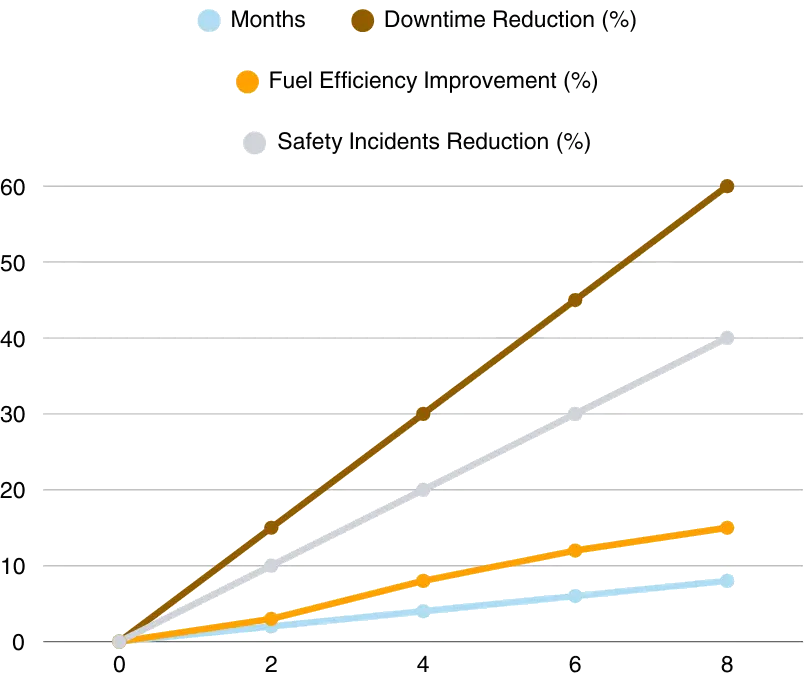

The implementation produced transformative operational and financial results:

-

Raw Material Reduction: A 10% decrease in usage, translating to substantial cost savings and lower waste.

-

Energy Efficiency: Energy consumption dropped by 12%, saving approximately $2 million annually.

-

Operational Gains: Furnace efficiency improved by 15%, reducing downtime and extending equipment life.

-

Environmental Benefits: Lowered carbon emissions supported regulatory compliance and sustainability goals.

-

Rapid ROI: Investment costs were recovered within just one year, affirming the financial viability of the AI solution.

Future

Scaling and Innovating Further

Solution Expansion

Extending the AI system to all furnaces across the facility.

Predictive Maintenance

Incorporating AI tools for equipment health forecasting and downtime prevention.

Collaborative Innovation

Engaging in ongoing R&D partnerships to push the boundaries of industrial AI for sustainability and operational excellence.