Energy Management for Oil Boilers

Executive Summary

Industrial boilers are critical for steam generation in oil refining, but inefficient operations can lead to massive energy waste, increased costs, and environmental concerns.

Facing rising operational expenses and stricter emissions regulations, a leading refinery partnered with Synaptron to deploy an AI-powered energy optimization system. The solution combined IoT sensors, machine learning, and real-time automation to dynamically adjust boiler performance.

The results were dramatic:

-

$18 million in annual energy savings

-

Improved compliance with sustainability standards

-

Reduced manual intervention and maintenance costs

This case study details the implementation and long-term benefits of this cutting-edge energy management approach.

Challenge

Inefficient Boiler Operations Driving Up Costs

Energy Waste & High Costs

-

Suboptimal combustion processes led to excessive fuel consumption.

-

Lack of real-time adjustments resulted in heat transfer inefficiencies, increasing energy bills.

Manual Monitoring & Downtime

-

Operators relied on reactive adjustments rather than predictive optimization.

-

Frequent manual interventions caused production delays and higher labor costs.

Environmental & Regulatory Pressure

- Rising carbon emissions threatened compliance with environmental standards.

- The company needed a data-driven approach to meet sustainability goals.

Solution

AI-Powered Energy Optimization System

1. Real-Time Data Collection with IoT Sensors

-

Installed smart sensors to monitor:

-

Temperature, pressure, fuel flow rates

-

Emissions levels (CO₂, NOx, SOx)

-

Steam output and combustion efficiency

-

2. AI-Driven Predictive Analytics

-

Machine learning models analyzed historical and real-time data to:

-

Predict steam demand and adjust fuel input proactively.

-

Detect anomalies (e.g., incomplete combustion, heat loss).

-

Optimize fuel-air ratios for peak efficiency.

-

3. Automated Real-Time Adjustments

-

AI-controlled actuators dynamically fine-tuned:

-

Fuel injection rates

-

Airflow for optimal combustion

-

Pressure and temperature settings

-

4. Centralized Dashboard & Reporting

-

Live performance tracking with alerts for inefficiencies.

-

Automated compliance reports for emissions and energy usage.

Outcome

Measurable Efficiency Gains & Cost Savings

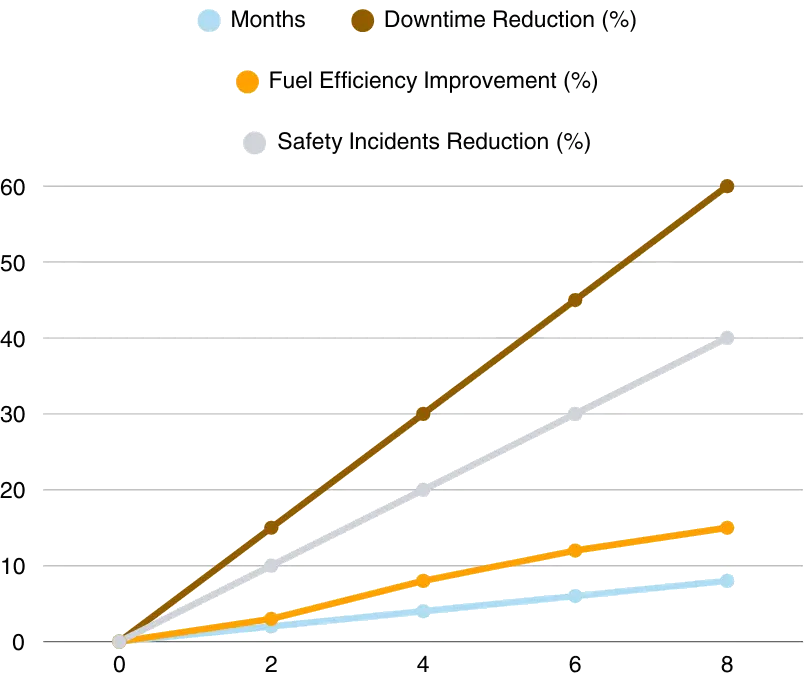

Operational Improvements

- 15% Reduction in Energy Consumption

-

Saved $18 million annually through optimized fuel usage.

-

- 10% Increase in Boiler Efficiency

-

Reduced downtime and maintenance costs by minimizing wear and tear.

-

- 20% Lower Carbon Emissions

-

Achieved regulatory compliance and improved sustainability metrics.

-

- ROI Achieved in 12 Months

-

The system paid for itself within a year due to energy savings.

-

The AI-driven energy management system has transformed our boiler operations. We’ve cut costs, reduced emissions, and improved efficiency—all with minimal manual intervention.

Future

Inefficient Boiler Operations Driving Up Costs

Next Steps for Continuous Improvement

- Expand to Additional Boilers – Deploy the system across the entire refinery.

- Predictive Maintenance Integration – Use AI to forecast equipment failures before they occur.

- Enhanced Sustainability Initiatives – Explore further carbon reduction strategies.

Synaptron’s Value Proposition

- End-to-End Energy Optimization – From hardware to AI integration.

- Industry-Specific Expertise – Deep knowledge of refinery operations.

- 24/7 Support & Continuous Upgrades – Ensuring long-term success.