AI-Based Vehicle Monitoring in Harsh Mining Environments

Executive Summary

Faced with high maintenance costs and frequent safety incidents, a large mining operation adopted an AI-based vehicle monitoring solution. The goal was to enhance the operational visibility of their vehicle fleet operating in extreme Canadian climates.

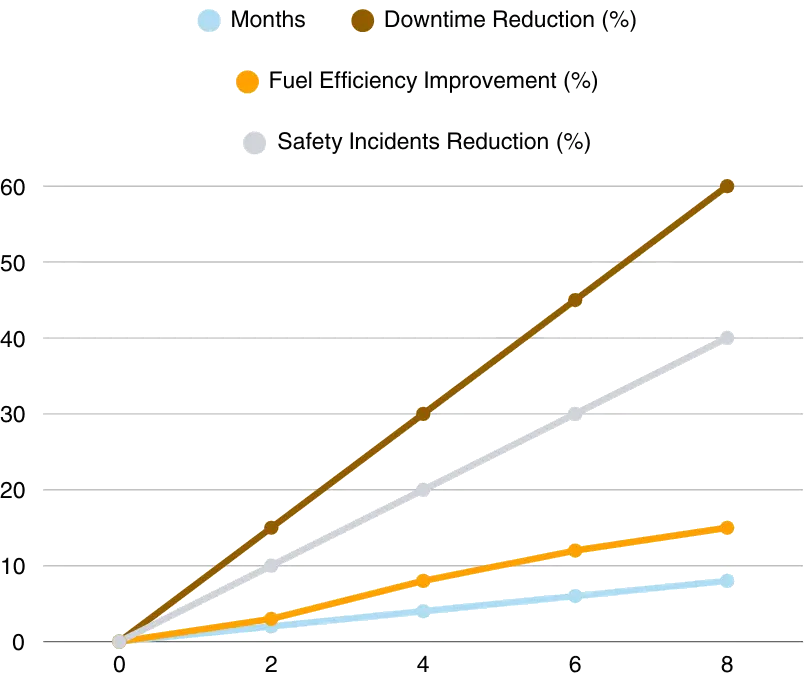

The results were transformative:

-

25% reduction in vehicle downtime

-

15% improvement in fuel efficiency

-

30% reduction in safety incidents

-

ROI achieved within just 8 months

Through predictive analytics, real-time monitoring, and seamless integration into existing systems, the solution significantly improved productivity and compliance.

Challenge

Operational and Environmental Hurdles

Open-pit mining fleets operate in some of the harshest environments imaginable:

Unpredictable Weather

Temperatures ranging from -40°C to +35°C

Risky Enviornment

Persistent dust, vibrations, and rugged terrain

Vehicle Failures

Frequent vehicle failures due to environmental stress

Driver Fatigue

Driver fatigue and a lack of real-time monitoring increasing the risk of accidents

These conditions resulted in:

Rising costs

Rising maintenance and repair costs

Production Halts

Frequent production halts

Safety Violations

Safety violations with potential regulatory consequences

Inconsistent Metrics

Inconsistent fleet performance metrics

Solution

AI-Based End-to-End Vehicle Monitoring System

The technology provider implemented a rugged, modular, and scalable solution specifically designed for mining environments.

1. Hardware Deployed

-

Rugged IoT Sensors: Installed to monitor real-time parameters such as engine temperature, tire pressure, fuel levels, and vehicle vibrations.

-

High-Durability Cameras: Provided driver monitoring and obstacle detection under rough conditions.

2. AI and Software Layer

-

Anomaly Detection: Machine learning models flagged abnormal operational conditions early.

-

Predictive Maintenance: Time-series models forecasted component failures (e.g., transmission, engine).

-

Computer Vision: Detected driver fatigue and environmental obstacles using camera data.

-

Cloud Dashboard: Centralized interface for real-time tracking, historical analysis, and compliance reporting.

3. Communications Infrastructure

-

Built on LoRaWAN and 5G, enabling low-latency, high-reliability communication between vehicles and the command center.

4. Integration and Process

-

Fully integrated with the existing ERP and maintenance systems, allowing automated ticket generation, tracking, and reporting.

-

Phased rollout: Site assessment → Sensor installation → Model tuning → System audits.

Outcome

Business and Operational Impact

-

25% Downtime Reduction: Predictive alerts prevented critical failures before they happened.

-

15% Fuel Efficiency Gain: Optimized driving patterns and idle time analytics.

-

30% Fewer Safety Incidents: Real-time alerts reduced the chances of accidents in remote locations.

-

20% Lower Maintenance Costs: Reduction in unplanned servicing and part replacements.

-

Full ROI within 8 Months: Through cost savings and efficiency improvements.

This deployment also led to regulatory compliance improvements, helping avoid fines and boosting the organization’s safety scorecard.

Future

Scaling Smarter, Driving Greener

Global Expansion

Rolling out the solution across additional mining operations.

Advanced Analytics

Adding modules to optimize fuel usage and reduce carbon emissions.

Sustainable AI

Partnering on future initiatives for environment-conscious and AI-enhanced mining operations.