AI-Based OT Solutions: Part 1

Executive Summary

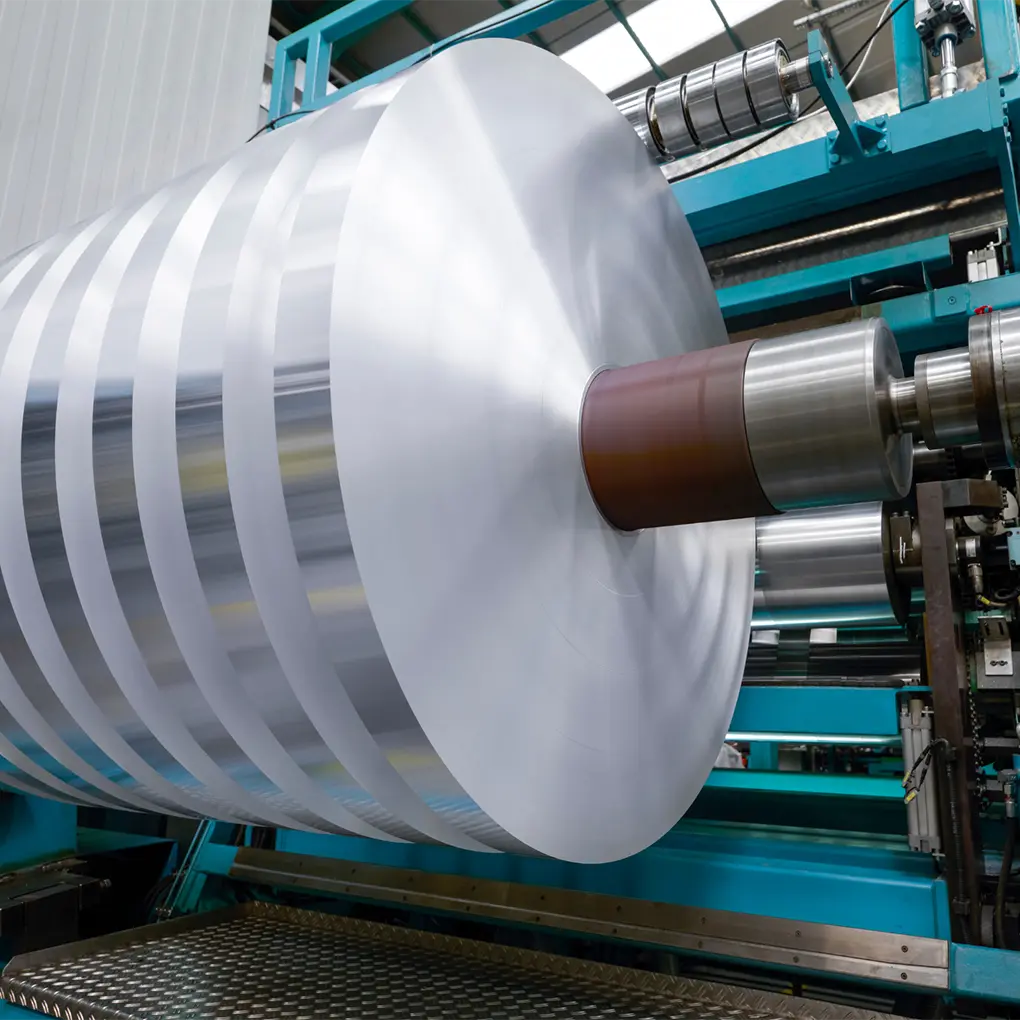

A major aluminium manufacturing facility was facing rising energy costs, frequent equipment breakdowns, and underperforming production metrics. To address these issues, an advanced AI-based OT system was implemented to enable predictive maintenance, energy savings, and continuous process improvement.

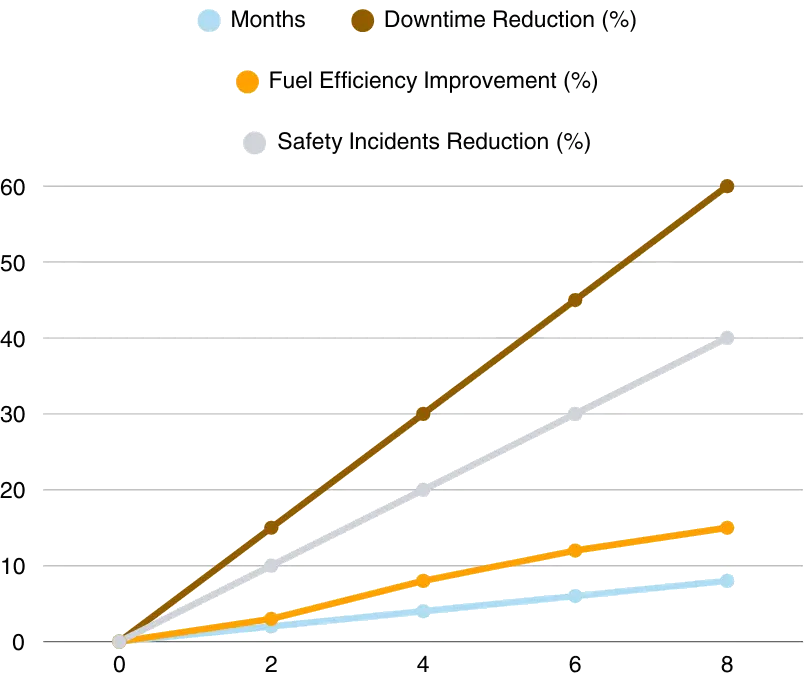

Results achieved within 10 months:

-

20% increase in production efficiency

-

15% reduction in energy consumption

-

30% drop in unplanned downtime

-

Full ROI within 10 months

These outcomes were made possible by intelligent hardware-software integration that delivered real-time operational insights and automated process adjustments.

Challenge

Operational Inefficiencies in Energy-Heavy Processes

The production process involved rolling, annealing, and coating aluminium—activities that are inherently energy-intensive and sensitive to process variations. The plant was plagued by:

Energy Waste

Inefficient furnace temperatures and rolling pressures led to high energy costs.

Reactive Maintenance

Frequent equipment failures due to lack of predictive analytics.

Downtime and Delays

Manual interventions disrupted production and led to unmet targets.

Competitive Pressure

Rising operational costs and shrinking margins demanded transformation.

A modern solution was needed to intelligently control and optimize equipment and process variables in real time.

Solution

End-to-End AI-Based OT System for Smart Manufacturing

A robust OT solution was deployed to enable real-time optimization and predictive control across critical operations.

1. Hardware Implementation

-

IoT Sensors: Installed across key machinery such as rolling mills and furnaces to collect temperature, pressure, vibration, and energy data.

-

Edge Devices: Enabled real-time processing and decision-making close to the data source.

2. AI Software Stack

-

Predictive Maintenance: Machine learning models anticipated equipment wear and tear (e.g., rolling mill bearings), preventing breakdowns.

-

Energy Optimization: Adjusted process parameters like furnace temperature and rolling pressure to reduce energy usage.

-

Process Optimization: Improved product quality and throughput through continuous AI-driven adjustments.

3. Visualization & Reporting

-

Dashboard Interface: Delivered live production metrics, energy usage, and equipment health data to operators and decision-makers.

-

SCADA & MES Integration: Ensured centralized monitoring and seamless data flow for operational visibility.

Outcome

Tangible Improvements in Operations and Financial Performance

-

20% Boost in Production Efficiency: AI-driven control reduced waste and improved yield.

-

15% Energy Savings: Better thermal and mechanical management lowered electricity and fuel costs, saving approximately $1.8 million annually.

-

30% Less Unplanned Downtime: Predictive alerts enabled timely intervention and increased equipment reliability.

-

Faster Maintenance: Early warning systems reduced emergency maintenance events and prolonged equipment life.

-

ROI in 10 Months: The combined benefits rapidly justified the initial investment.

These achievements strengthened the manufacturer’s ability to meet production demands while reducing environmental impact and cost burdens.

Future

Scaling AI Across the Factory Floor

Scaling the Solution

Expanding to all production lines and equipment types.

Sustainability Insights

Adding tools to track and reduce the plant’s carbon footprint.

Collaborative Innovation

Joint R&D initiatives focused on next-generation AI features for smart manufacturing.